In the dynamic landscape of modern manufacturing, efficiency and precision in material handling can significantly impact productivity. Electric hydraulic scissor lifts have emerged as indispensable tools in the realm of lifting logistics, transforming the way factories manage and maneuver materials. This blog explores the role of these innovative lifts in optimizing material handling processes within factory environments.

Elevating Efficiency with Precision

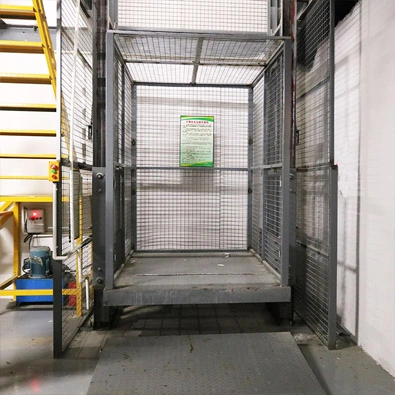

One of the primary advantages of electric hydraulic scissor lift in factories is their ability to elevate materials with precision. Whether it's positioning raw materials on production lines or transferring finished products between different stages of manufacturing, these lifts offer a level of accuracy that manual handling or traditional equipment may struggle to achieve. The vertical mobility and controlled lifting mechanisms ensure that materials are placed exactly where they need to be, minimizing errors and enhancing overall efficiency.

Space Optimization in Busy Work Environments

Factories are often characterized by limited floor space and a high density of machinery. Electric hydraulic scissor lifts, with their compact designs and versatile configurations, allow for optimal use of available space. Their ability to navigate through tight spaces and lift materials to varying heights enables factories to make the most of their spatial constraints. This space optimization not only enhances the overall layout efficiency but also contributes to a safer and more organized working environment.

Streamlining Workflow with Quick Vertical Access

Material handling in factories involves the constant need for vertical access to various levels of production. Electric hydraulic scissor lifts offer a swift and efficient solution. With the ability to reach considerable heights, these lifts streamline workflow by eliminating delays associated with manual transfers or the use of traditional weight lifting machine vehicle. The quick vertical access they provide ensures a seamless progression of materials through different stages of production, ultimately reducing downtime and enhancing overall output.

Enhanced Safety Standards

Safety is paramount in any manufacturing setting, and electric hydraulic scissor lifts are designed with this priority in mind. The lifts come equipped with safety features such as emergency stop buttons, non-slip platforms, and railings, ensuring a secure working environment for operators. By minimizing the risks associated with manual material handling or the use of less sophisticated lifting equipment, these lifts contribute to a safer workplace and help factories adhere to stringent safety standards.

Adaptability to Varied Load Capacities

Factories deal with a diverse range of materials, each varying in size and weight. Electric hydraulic scissor lifts are designed to accommodate this diversity, offering models with different load capacities to suit specific material handling needs. From lighter loads in assembly lines to heavier materials in storage facilities, these lifts provide the adaptability required to handle a broad spectrum of products, making them a versatile asset in the realm of lifting logistics.

In conclusion, the integration of electric hydraulic scissor lifts in factories marks a transformative step in material handling efficiency. These lifts not only enhance precision and safety but also contribute to the overall optimization of workflow and utilization of space. As manufacturing continues to evolve, the role of electric hydraulic scissor lifts as key players in lifting logistics becomes increasingly evident, providing factories with the tools they need to meet the demands of a fast-paced and competitive industrial landscape.